INTRODUCTION

Joint-Stock Company Nizhny Novgorod Engineering Company Atomenergoproekt

(hereinafter referred to as JSC NIAEP or NIAEP)

Details:

Postal address: 3, Svoboda sq., Nizhny Novgorod, 603006, Russia

Tel.: +7 831 421 79 00

Fax: +7 831 419 84 90; +7 831 421 06 04

Website: http://www.niaep.ru

E-mail: niaep@niaep.ru

Shareholders:

As of December 31, 2012 the sole shareholder of JSC NIAEP is Joint-Stock Company Atomic Energy Power Corporation (JSC Atomenergoprom).

Registrar:

The JSC NIAEP registered stock holders’ register is kept by Open Joint-Stock Company Registrator R.O.S.T.

Address: 18, build.13, Stromynka str., Moscow, Russia.

Auditor:

The JSC NIAEP external auditor is the Limited Liability Company Financial and Accounting Consultants (FBK Ltd.).

Postal address: 44/1, build. 2AB, Myasnitskaya str., 101990, Moscow, Russia

Tel.: +7 495 737 53 53.

Legal address: 44/1, build. 2AB, Myasnitskaya str., 101990, Moscow, Russia

Authorized capital:

As of December 31, 2012 the authorized capital of JSC NIAEP amounted to 500,001,877 rubles.

About this Report

The 2012 Public Annual Report (hereinafter referred to as the Report) is the fifth integrated report of JSC NIAEP (hereinafter referred to as NIAEP) disclosing its financial and non-financial performance results. The previous report was issued in 2012. The report is made in Russian and English and is available online.

Scope of Report

This Report covers the activity of NIAEP during the period from January 1, 2012 to December 31, 22. The Report also includes information about Joint-Stock Company Atomstroyexport (hereinafter referred to as ASE) with regard to some aspects of performance. This is due to establishment of Integrated Company JSC NIAEP – JSC ASE in 2012 (hereinafter referred to as NIAEP-ASE or the Company). With regard to NIAEP subsidiaries and affiliates, the Report includes information in the field of human resources management only. This seems to be reasonable, so far as the NIAEP final financial indices are not changed considerably by the intra-company balance of the subsidiaries’ financial indices; moreover, the NIAEP subsidiaries and affiliates bring no significant environmental impact 1. Only some aspects of the NIAEP Moscow Branch activity are presented, as it was established in 2012.

No material changes in data measurement methods and calculations were made.

Defining Report Content

The defining content process is based on consultations with interested parties. Feedback received from them during preparation of the previous report was taken into account (see Annex No. 11 Plans and Obligations to Interested Parties) and four dialogues as follows were carried out with the interested parties during preparation of the present:

1. January 30, 2013, Concept of 2012 Annual Report;

2. March 13, 2013, NIAEP-ASE Integrated Company Strategy;

3. March 13, 2013, Sustainable Development;

4. April 24, 2013, Public Consultations Regarding the Report Draft.

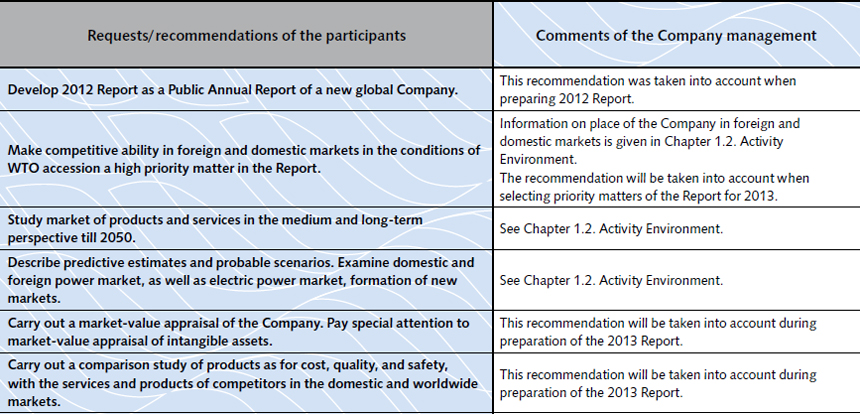

The Company has taken into account all comments and suggestions on information disclosure in the Report for 2012. The data regarding cooperation with the interested parties during preparation of the 2012 Report is given in Chapter 7.6.2 Dialogues with Interested Parties during Report Preparation, Chapter 7.6.3 Public Consultations on Report, and Annex No. 11 Plans and Obligations to Interested Parties.

According to the results of the Report discussion with the interested parties, elaboration of NIAEP-ASE Integrated Company strategy was named the most significant task set for 2013. In this connection the first-priority subject of the Report was defined as the NIAEP-ASE Integrated Company Strategy. This subject is covered by Section 2 Strategy. Moreover, information regarding some specific aspects thereof is specified in other sections of the Report.

Standards and Regulatory Requirements

• Policy of State Atomic Energy Corporation ROSATOM in the field of public reporting;

• Federal Law on Joint-Stock Companies No. 208-FZ dated December 26, 1995.

• Order of the Federal Commission for the Securities Markets of Russia (FCSM) on Approval of Regulations Concerning the Disclosing of Information on Equity Securities to Emitters No. 06-117/pz-n dated October 10, 2006.

• Order of the FCSM of Russia on Recommendations Concerning Application of the Code of Corporate Conduct No. 421/r dated April 4, 2002.

• Order of the FCSM of Russia on Methodological Recommendations Concerning the composition and Form of Presentation of Data on Observance of the Code of Corporate Conduct in Annual Reports of Joint-Stick Companies No. 03-849/r dated April 30, 2003.

• Federal Law on National Security Information No. 5485-1 dated July 21, 1993.

• Federal Law on Commercial Confidential Information No. 98 dated July 29, 2004.

• Federal Law on Information, Informational Technologies and Information Protection No. 149-FZ dated July 27, 2006.

• Federal Law on Accounting No. 129-FZ of November 21, 1996.

• Typical public annual accounting standard of key organizations (for the purpose of public accounting) of the State Atomic Energy Corporation ROSATOM;

• JSC NIAEP Public Annual Accounting Standard;

• Code of Ethics of the State Atomic Energy Corporation ROSATOM;

• AA1000 Series International Standards;

• Global Reporting Initiative Sustainability Reporting Guidelines (GRI G3.1);

• Industry-specific supplement to the GRI Guidelines Construction and Real Estate Sector Supplement (CRESS) designed for construction companies;

• Primary Integrated Accounting Standard of the International Integrated Reporting Committee (IIRC).

Application of IIRC Recommendations

In the process of the Report preparation we took into account recommendations contained in the Primary Integrated Accounting Standard of the International Integrated Reporting Committee (IIRC). The main elements were reported in accordance with these recommendations:

• Overview and context of the company’s activity (Section 1 About our Company);

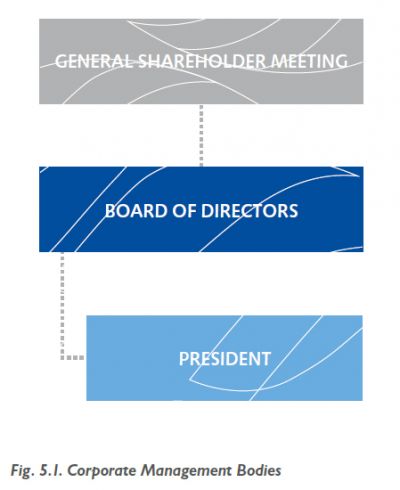

• Management (Section 5. Management System);

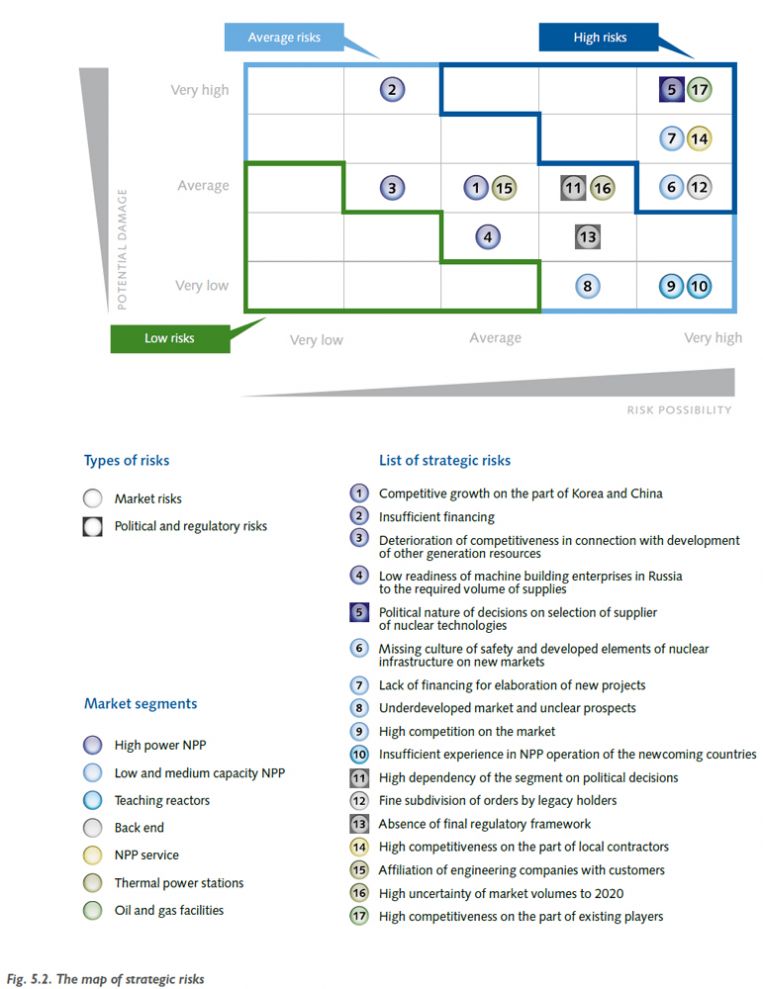

• Opportunities and risks (Message from the President of JSC NIAEP and from the Chairman of the Boards of Directors of JSC NIAEP; Section 2. Strategy; Chapter 5.2. Risk Management);

• Strategy and plans on resources allocation (Section 2. Strategy);

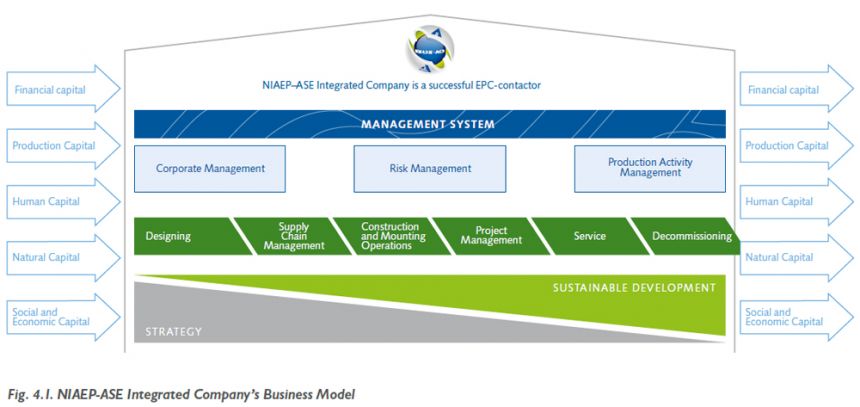

• Business model (Section 4 Business Model);

• Performance results (Major Performance Indices; Key Events Calendar; Section 3. Performance Results of Strategic Importance; Section 7. Fund Development);

• Future prospects (Section 2. Strategy; Section 7. Fund Development).

The main difference of this Report from the NIAEP previous public annual reports consists in that the efficiency in the field of sustainable development is presented as activity on fund development:

• Economic efficiency – Chapter 7.1. Financial Capital, Chapter 7.2. Production Capital, Chapter 7.5. Social and Economic Capital;

• Social efficiency – Chapter 7.3. Human Capital, Chapter 7.5. Social and Economic Capital;

• Environmental efficiency – Chapter 7.4. Natural Capital.

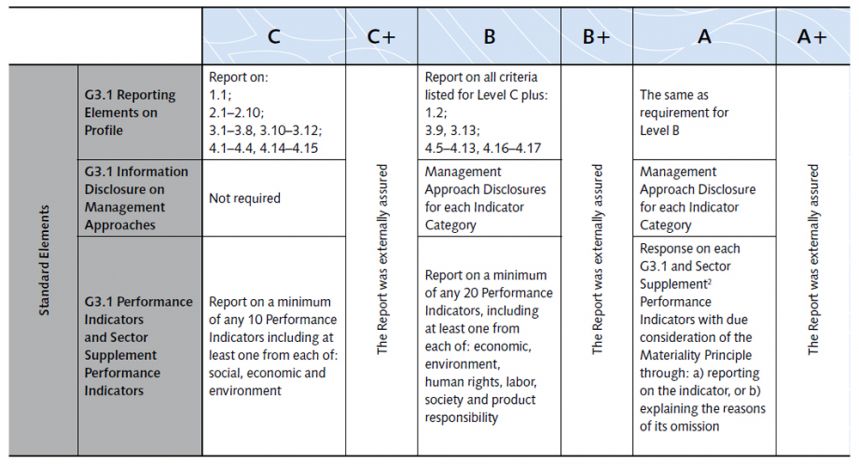

GRI Application Level

Assurance of Report Information Credibility

The Report was externally assured by Closed JointStock Company NP Consult which confirmed the A+ GRI Application Level. The external audit report on assurance of non-financial statements is given in the Annex No. 7.

Management and audited financial statements of NIAEP according to the Russian Accounting Standards were used during preparation of this Report. The Report Draft was reviewed by the NIAEP Internal Control and Audit Department. Conclusion on results of the review is given in Annex No. 8

Disclaimer on Disclosure of Pro Forma Information

The Report contains pro forma statements with regard to production, financial, economic, and social indicators characterizing further development of the Company.

Implementation of assumptions and intentions is directly connected with political, economic, social, and legal situation. In this connection actual performance results of the Company may differ from the pro forma statements.

1 In the field of HR management of subsidiaries and affiliates NIAEP keeps records with regard to staff force only.

2 Branch application in final version.

Message from the President of JSC NIAEP

Dear Colleagues!

On some extent 2012 is of historical importance for us. That year we made a decision on establishment of NIAEP-ASE Integrated Company. Merger with JSC ASE was carried out in accordance with the NIAEP Strategy adopted in 2010 and the Strategy on Engineering Development in Russia of State Corporation ROSATOM.

On some extent 2012 is of historical importance for us. That year we made a decision on establishment of NIAEP-ASE Integrated Company. Merger with JSC ASE was carried out in accordance with the NIAEP Strategy adopted in 2010 and the Strategy on Engineering Development in Russia of State Corporation ROSATOM.

NIAEP-ASE Integrated Company shall form the basis for development of engineering business of State Corporation ROSATOM. We face the ambitious task of becoming the leading engineering company not only in Russia, but also worldwide. I am confident that our team of highly professional and responsible employees is equal to this task.

Integration of NIAEP advanced expertise in the field of NPP engineering and construction and ASE unique experience in international project management has significantly extended opportunities of our engineering company both on the Russian and global markets. It shall be noticed that our Company has more than 20 generating units, which are designed and constructed both in Russia and abroad.

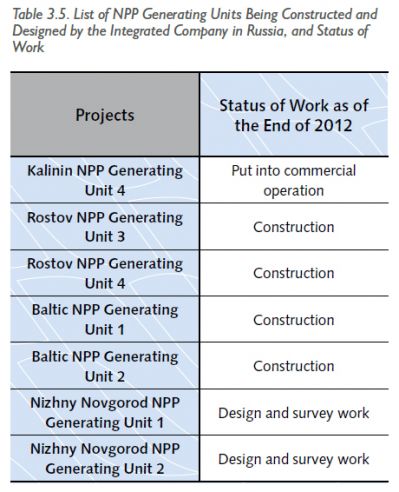

Our most significant 2012 achievement is the commercial operation of generating unit 4 of the Kalinin NPP which took place on September 25. This achievement in the nuclear industry is of nationwide importance. Currently, Kalinin NPP generating unit 4 is the most advanced one in the territory of Russia. The construction proved that we are capable of keeping projects both on schedule and under budget. The main contributors to this achievement, our colleagues and employees, received state and official awards.

The Company proceeds with construction of units 3 and 4 of the Rostov NPP and units 1 and 2 of the Baltic NPP. Since October 2012 NIAEP-ASE has been the General Designer and General Contractor of the Kursk NPP second stage construction. It is planned to apply the most advanced reactor of VVER-TOI type in the structure of this power plant.

The second stage construction of the Yuzhnouralsk HPP is well under way; commissioning of unit 1 is planned for 2013.

Quite a number of significant events took place on international markets.

NIAEP is an open and transparent company which annually reports on its activity to the interested parties. Year after year we increase the level of reporting. I am proud to announce that in 2009, 2010, and 2012 our Company’s annual reports were recognized the best in the nuclear power industry. This annual public report is prepared to acquaint all interested parties with the detailed results of our activity in 2012.

In the end of the year the reactor start-up of Kudankulam NPP unit 1 in India was launched. Initial concrete placement for Tianwan NPS unit 3 in China took place on December 27.

On July 18, 2012 we signed the general contract on construction of the Belarusian NPP. Under this Contract, the Republic of Belarus will receive a new ready-to-operate nuclear power plant in compliance with all international safety standards.

In 2012 we submitted a bid to the Temelin NPP (Czech Republic) tender.

Our Company has also carried out significant large-scale work on spent fuel and nuclear waste handling at Russian and foreign facilities.

Entering the market as a global engineering company, in our activity we attribute equal importance to innovation, safety, and quality. We actively introduce the Multi-D technology to form the management system on its basis for control over the whole NPP life cycle from designing to decommissioning. This technology enables 3D-modelling of construction and mounting operations with consideration of optimal employment of resources prior to start of actual construction. This technology provides the possibility to proceed to a modeling of design and construction work on the base of a 3D model with the optimized use of resources. Its application reduces duration of construction and cost of projects and simultaneously increases labor productivity, work quality, and safety level at nuclear power facilities. This new technology is utilized for NPP engineering with VVER-TOI reactor.

In 2012 NIAEP arranged International Research and Practice Forums on Multi-D Technology at the Nizhny Novgorod Fare. We are proud to say that the Forum is becoming an inportant platform where world-class experts can share their opinions. Over 600 participants representing nearly 100 companies and 20 countries were registered during the last Forum.

Among our major tasks for 2013 we highlight elaboration of NIAEP-ASE Integrated Company Strategy.

Priority objectives of the Company for 2012–2016 consist in performance of all Investment Program implementation plans declared as of today.

In its activity NIAEP is always guided by sustainable development principles. Human capital is one of the Company’s first priorities. We create new working places fitted out with modern equipment, providing our employees with safe working conditions, respectable salary, and social package and helping them to develop their professional skills and move up the career ladder.

| President of JSC NIAEP |

|

V.I. Limarenko |

Message from the Chairman of the Board of Directors of JSC NIAEP

Dear Ladies and Gentlemen!

Reviewing the 2012 annual results, the NIAEP Board of Directors is pleased to declare: NIAEP-ASE Integrated Company established one year ago successfully performating the Strategy of State Corporation ROSATOM on Industry-Specific Engineering Development and demonstrates readiness to make fresh gains in Russia, as well as worldwide.

Today, JSC NIAEP is one of the leading engineering companies in Russia. During construction of Kalinin NPP unit 4, commissioned in 2012, JSC NIAEP performed the functions of the General Contractor. Kalinin-4 is the most significant project for the national nuclear power industry which demonstrated high professionalism of Russian nuclear experts. The unit was constructed green field within the time limits set and with considerable cost cutout.

Currently, NIAEP is engaged in construction of units 3 and 4 of the Rostov NPP, units 1 and 2 of the Baltic NPP, and second stage construction of the Yuzhnouralsk HPP and the Kursk NPP. These large-scale projects prove customers’ confidence in the Company and its management.

In 2012 JSC NIAEP acted as Management Company of JSC Atomstroyexport, having successfully accomplished such tasks as full capacity operation of the Bushehr NPP (Iran), preparation for a reactor start-up of the Kudankulam NPP (India), initial concrete placement for Tianwan NPP unit 3 (China), construction site mobilization for the Ostrovets NPP (Belorussia), design and survey work organization at the Akkuyu NPP (Turkey), the Ninh Thuan NPP (Vietnam) and the Ruppur NPP (Bangladesh).

The NIAEP Board of Directors is confident that the Integrated Company will become the center of industry-specific engineering business development. Company’s priorities remain unchanged: quality, innovativeness, efficiency, and safety above all. The high culture of environmental safety is an essential competitive advantage of NIAEP, necessary for successful promotion of domestic nuclear technologies on the world market.

Chairman of the Board of Directors

of JSC NIAEP,

Deputy General Director and

Director of Department for

Development and Global Business of

State Corporation ROSATOM |

|

K.B. Komarov

|

Key Performance Indices

Table 1. Dynamics of Key Performance Indices for 2010–2013

Interactive analysis

Sales revenue

ths.

- Sales revenue, ths. rub.

- Net profit, ths. rub.

- Workforce productivity, ths. rub./person

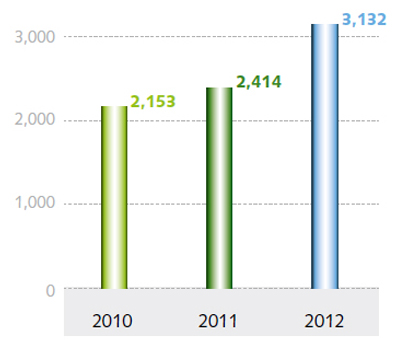

- Average number of listed employees, people

- Quantity of power generating units under construction within the accounting period

- Tax deductions to the federal, regional, and local budgets (excluding personal income tax and state duties), ths. rub.

- Social expenditures, ths. rub.

- Internal performance (added value),%

3 2013 indices are of pro forma nature and may change in future.

4 For the purpose of pro forma statement, consolidation exclude subsidiaries and ASE, as the average

number of listed employees for 2013 has not been approved by State Corporation ROSATOM yet.

Key Events Calendar 2012

Key Events Calendar 5

February, 21

• The NIAEP Board of Directors made a decision on establishment of the Belarusian Representation.

February, 24

• The Company launched construction of Baltic NPP unit 1.

March, 14

• A Belorusian delegation headed by the First Deputy Prime-Minister V.I. Semashko visited NIAEP.

March, 20

• The Company launched preparatory work on construction of Belarusian NPP units 1 and 2 in the Republic

of Belarus.

April, 5–6

• A field meeting of the VVER-TOI Project Management Board under the guidance of the Deputy General

Engineering Director of OJSC Rosenergoatom Concern took place in NIAEP.

April, 25

• NIAEP Director V.I. Limarenko was elected to the Russian Board of Employers in Nuclear Power Engineering,

Power Engineering and Science Sector.

April, 30

• Safety systems of Kudankulam NPP unit 1 being constructed by the Integrated Company were successfully

tested.

May, 14

• The Company launched construction of Yuzhnouralsk HPP-2 unit 2.

May, 18

• Bureau Veritas Certification (an independent agency for certification of management systems) completed

recertification audit of the integrated management system (IMS) of ASE, NIAEP Moscow Branch, and

NIAEP Moscow Representation. Upon completion of the audit certificates were issued confirming

compliance of IMS with the requirements of ISO 9001:2008, ISO 14001:2004, and OHSAS 18001:2007.

May, 24

• The NIAEP Board of Directors made a decision on establishment of the Navashino Branch.

June, 14–15

• NIAEP organized the 2nd International Research and Scientific Forum on Life Cycle Management of

Complex Engineering Facilities and Development of Competitive Construction Technologies.

5 The Milestone Schedule Section includes information concerning both the Integrated Company in whole, and NIAEP and ASE separately.

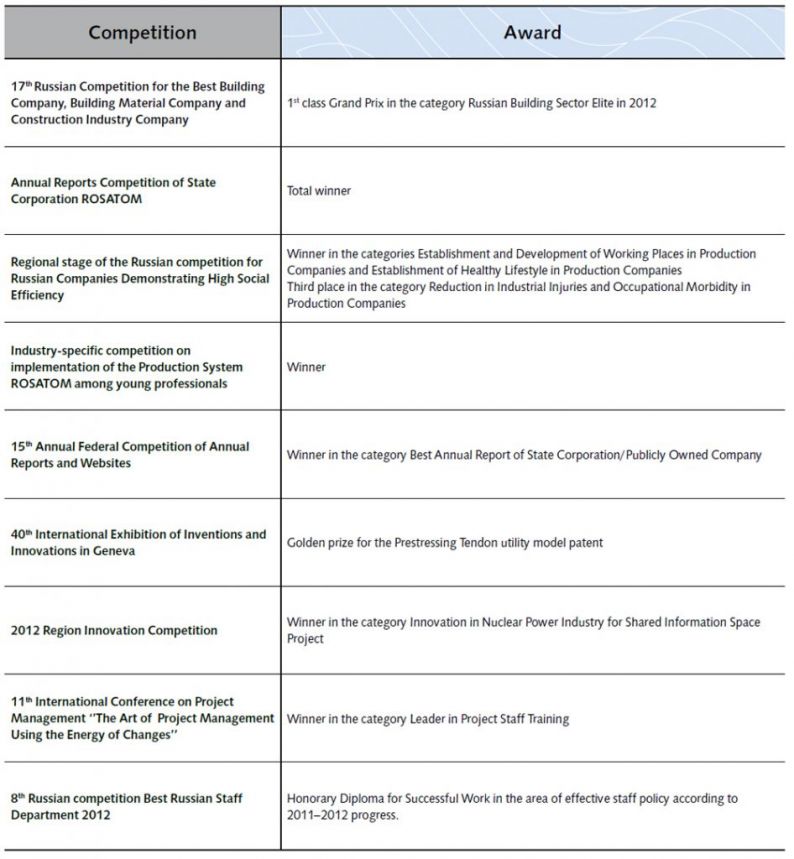

Awards

ABOUT OUR COMPANY

Description of Activity

NIAEP-ASE Integrated Company bills itself as the leader in the nuclear power engineering business in Russia. The Company renders services on designing, construction, and decommissioning of complex engineering facilities such as:

- Nuclear power plants abroad;

- Nuclear power plants in Russia;

- Radioactive waste and spent fuel handling units;

- Heat power engineering facilities.

In addition, NIAEP-ASE Integrated Company supplies equipment for complex engineering facilities.

Information on performance results is given in Section 3 Performance Results of Strategic Importance.

Presence Regions

The NIAEP central office is located in Nizhny Novgorod, and the ASE central office in Moscow.

The Company operates in 14 countries: Armenia, Bangladesh, Belarus, Bulgaria, Hungary, Vietnam, India, Iran, China, Russia, Slovakia, Turkey, Ukraine, Czech Republic.

NIAEP Subsidiaries:

- Limited Liability Company Construction and Erection Department No. 1,

- Limited Liability Company Construction and Erection Department No. 2,

- Limited Liability Company Volgodonsk Erection Department.

Affiliates:

- NIAEP Udomlya Branch – Kalinin NPP General Contractor Directorate

- NIAEP Volgodonsk Branch – Rostov NPP General Contractor Directorate

- NIAEP Baltic Branch – Baltic NPP General Contractor Directorate

- NIAEP Yuzhnouralsk Branch

- NIAEP Moscow Branch

- NIAEP Kursk Branch – Kursk NPP General Contractor Directorate

- NIAEP Navashino Branch – Nizhny Novgorod NPP General Contractor Directorate.

Representations:

- NIAEP Moscow Representation,

- NIAEP St. Petersburg Representation,

- NIAEP Volgodonsk Representation,

- NIAEP Kharkov Representation,

- NIAEP Belarusian Representation.

Membership in Associations

- Russian Industrial Federation of Employers in Nuclear Power Engineering, Power Engineering and Science Sector;

- Association of Innovative Designing;

- European Utility Requirements Organization (EUR);

- Self-Governing Organization Non-Commercial Partnership SOYUZATOMGEO Association of Organizations for Engineering Surveys During Architectural and Structural Designing, Construction, Reconstruction, and Capital Repair of Atomic Industry Facilities;

- Self-Governing Organization Non-Commercial Partnership SOYUZATOMSTROY Association of Organizations for Construction, Reconstruction, and Capital Repair of Atomic Industry Facilities;

- Self-Governing Organization Non-Commercial Partnership SOYUZATOMPROEKT Association of Organizations for Architectural and Structural Designing of Atomic Industry Facilities;

- Czech Nuclear Forum.

Historical Background

1951

- Establishment of the Gorkovskoye Department of the Teploenergoproekt Institute. The Institute was mainly engaged in designing of thermal power facilities.

- NIAEP is a successor of the Gorkovskoye Department of the Teploenergoproekt Institute.

1968

- The Institute began to work in the atomic energy industry. A specialized NPP planning and design office was established. The startup project of the office was Armenian NPP.

1976

- Commissioning of Armenian NPP unit 1.

1970–1990

- The Institute designed Kalinin NPP-1 unit 1 and the Rostov NPP. Starting from 1990 NIAEP projects included Armenian NPP-2, the Rostov NPP-2, the Balakovo NPP, and the Novovoronezh NPP-2.

1996

- The Institute entered the international market of NPP designing.

1998

2007

- Federal State Unitary Enterprise NIAEP was transformed into Engineering Company NIAEP operating according to the EPCM model. In accordance with it NIAEP began to perform the whole scope of work on NPP construction on its own.

2011

- NIAEP entered the international market of NPP construction.

2012

- Establishment of NIAEP-ASE Integrated Company. NIEAP became the managing company of ASE.

Activity Environment

Russian NPP Construction Market

Currently, 10 nuclear power plants operate in Russia (total of 33 generating units with design capacity of 24.2 GW) generating about 16% of the total electric energy produced.

Scope and prospects of development of the Russia’s NPP construction market are defined in the Long-Term (2009–2015) Activity Program of State Corporation ROSATOM approved by the Resolution of the Government of the Russian Federation No. 705 of September 20, 2008, and in the General Allocation Scheme of Power Industry Facilities till 2020 approved by the Order of the Government of the Russian Federation No. 215-r of February 22, 2008.

In 2012 four companies acted as general contractors in the market of nuclear-power facilities construction in the Russian Federation:

- NIAEP-ASE Integrated Company;

- Atomenergoproekt;

- SPbAEP;

- Uralenergostroy.

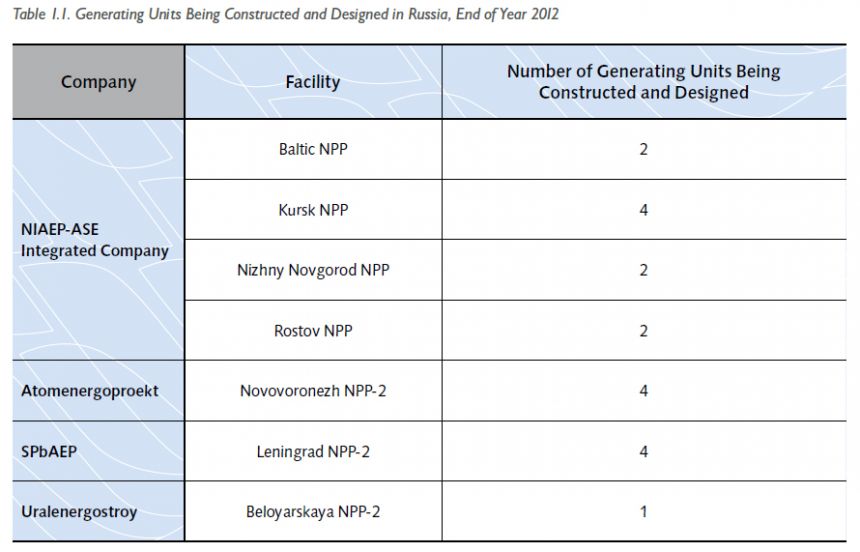

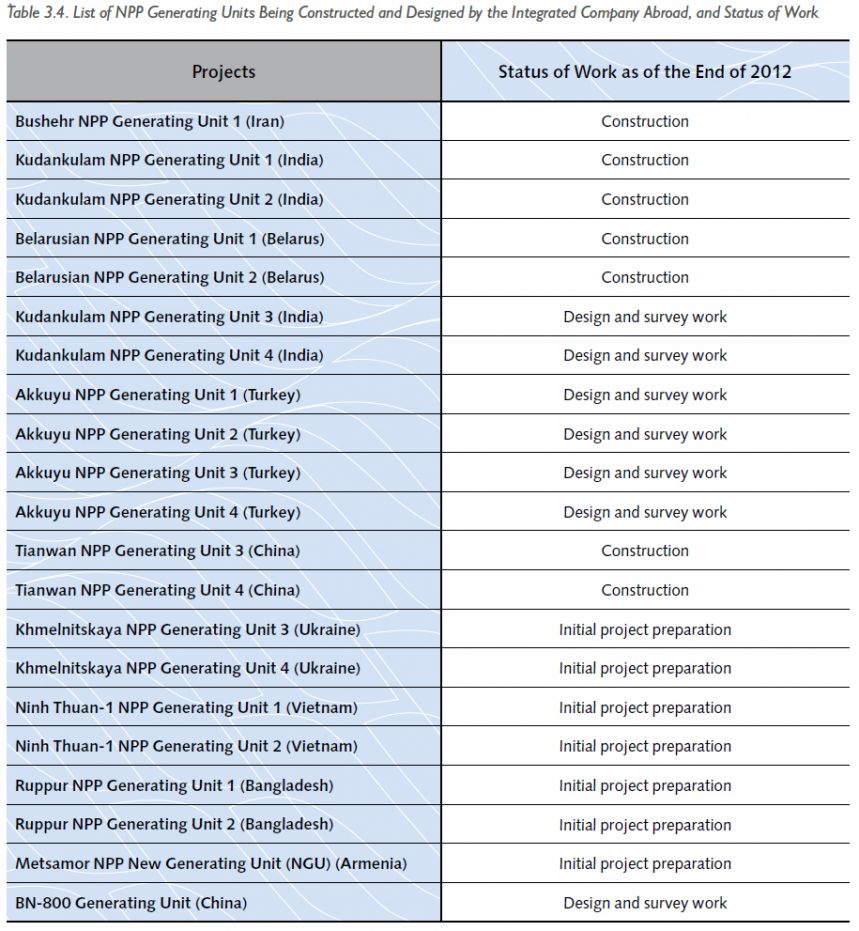

19 NPP generating units are being designed and constructed in the Russian Federation as of the end of year 2012. 10 of them are being constructed by the Integrated Company (see le 1.1).

The share of the Integrated Company in the NPP construction market of Russia amounts to 53% (see Fig. 1.1).

The main customer of the Integrated Company in the Russian market is the Rosenergoatom Concern being the member of State Corporation ROSATOM. State Corporation ROSATOM defines the Russian production distribution market, scope of work and duration of performance thereof.

Information on facilities being constructed and designed is given in Section 3 Performance Results of Strategic Importance.

Table 1.1. Generating Units Being Constructed and Designed in Russia, End of Year 2012

Fig. 1.1. Integrated Company Share in NPP Construction Market of Russia in 2012

International NPP Construction Market

According to the data of the World Nuclear Association (WNA) 6, over 60 generating units are currently at various stages of construction in 13 countries of the world. This estimate is confirmed by the IAEA report of September 9, 2012.

According to the IAEA report, the total NPP generating capacity in the world will increase from 375.3 GW to 501 GW (low scenario) or to 746 GW (high scenario) by 2030. If to assume that the average generating capacity of a reactor equals to 1,000 MW, one may forecast, that 126 generating units will be built under the low scenario and 371 – under the high scenario from 2010 to 2030.

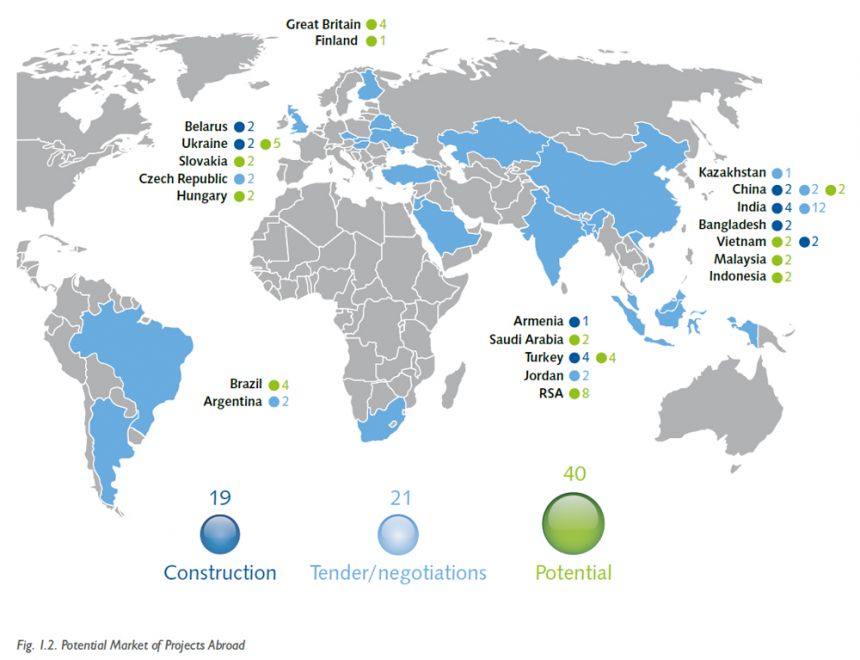

Till 2030 the potential stock of orders of State Corporation ROSATOM in the international markets may amount to 80 generating units (currently, title establishing documents have been signed with regard to 19 generating units, in addition, organizations of State Corporation ROSATOM carry on negotiations and participate in tenders with regard to 21 NPP generating units abroad, 40 generating units afford ground for expansion of Russian companies) (see Fig. 1.2).

The share of the Company in the global NPP design and construction market, including the Russian market, amounted to 33% in 2012, and in the period from 2010 to 2030 this index may reach 30% under the low scenario or 10% under the high scenario.

Information on facilities being constructed or designed abroad is given in Section 3 Performance Results of Strategic Importance.

Fig. 1.2. Potential Market of Projects Abroad

Service Market

Currently, the Integrated Company is rendering services – maintenance and repair, modernization, assets management – for the following nuclear power plants:

- Paks,

- Temelin,

- Bohunice ,

- Tianwan.

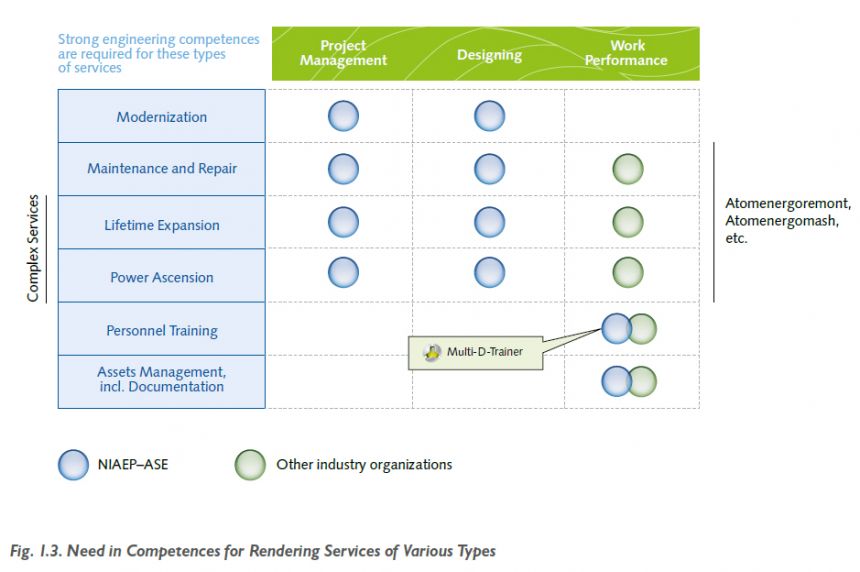

An assessment of market opportunities was carried out. Need in competences for rendering services of various types is described in Figure 1.3.

In the services market the Company plans to act as a general contractor of large projects on technical maintenance, repair and modernization, and as a consultant in the field of assets and education management.

Market of Radioactive Waste and Spent Fuel Reprocessing Facilities Construction

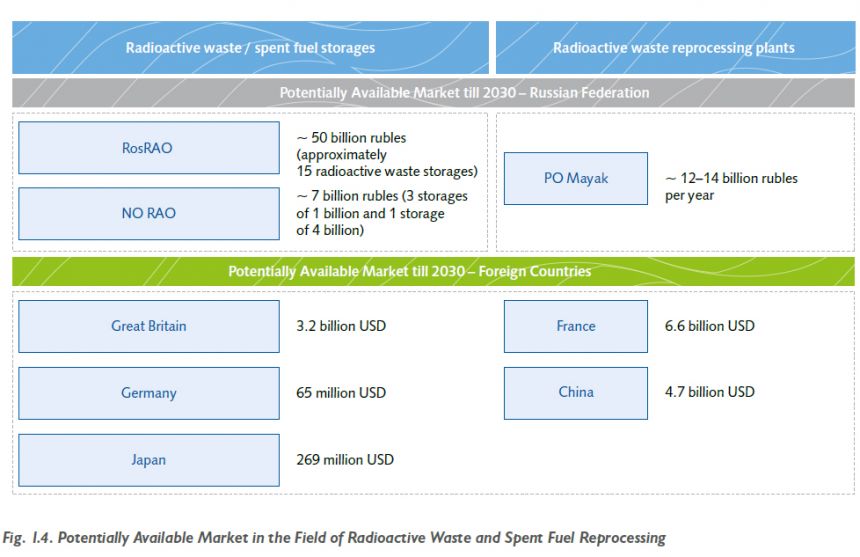

The market of facilities construction in the field of radioactive waste and spent fuel reprocessing is divided into two segments: construction of storages for radioactive waste and spent fuel and radioactive waste reprocessing plants. The total potential volume of foreign markets amounts to 348.5 billion dollars (see Fig. 1.4).

Fig. 1.3. Need in Competences for Rendering Services of Various Types

Fig. 1.4. Potentially Available Market in the Field of Radioactive Waste and Spent Fuel Reprocessing

In order to strengthen its market positions, the Integrated Company plans to increase its competencies as a general contractor and designer of radioactive waste and spent fuel reprocessing plants and to establish its own production base.

Market of Thermal Power Plants Construction

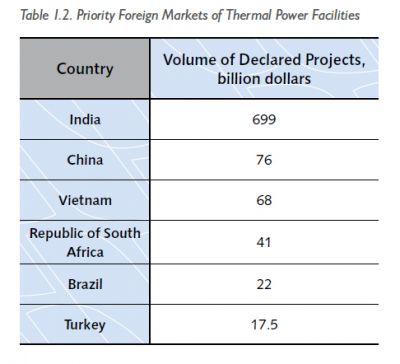

Currently, the volume of the Russian thermal power market is rather restricted. The existing projects on construction and commissioning of additional facilities till 2020 are contracted within the Capacity Delivery Agreements (CDA) by various contractors. Commissioning of facilities without CDA requires establishment of an investment support mechanism which has not been yet elaborated. According to Booz & Company 7, from 2012 to 2020 it is planned to commission thermal power stations with a total capacity of up to 10 GW. Till 2030 it is planned to commission 25 to 35 GW, in addition modernization of 7 to 10% of the existing TPP facilities will be required. The current share of the Integrated Company in the TPP construction market amounts to 5 to 7%.

In the conditions of a restricted TPP construction market in Russia the Integrated Company sets the following targets:

- Preservation of the current share in the Russian market;

- Implementation of 3 to 4 projects in 1–2 countries abroad (see Table 1.2).

Table 1.2. Priority Foreign Markets of Ther mal Power Facilities

6 See details: http://www.world-nuclear.org/

7 http://www.booz.com

Company video

Company video "NIAEP"

STRATEGY

Mission and Values

Our Mission

Based on our wide experience in implementation of projects in the nuclear power industry, we manage construction of complex engineering facilities, deliver value for the shareholder and provide achievement of shareholder’s goals in the Russian and international markets.

Our Vision

We strive to establish competitive business which successfully implements projects on construction of complex engineering facilities and is directed at maximization of shareholder value.

Our Values

Strategy Overview

Strategy Overview 8

Fig. 2.1. Strategic Initiatives

of State Corporation ROSATOM

in the Engineering Business

The NIAEP strategy till 2017 was approved by State Corporation ROSATOM and ratified by an order of the NIAEP Directorate in 2010. In the beginning of 2012 the NIAEP strategy was considerably amended in connection with the NIAEP and ASE merger. In 2013 it is planned to elaborate NIAEP-ASE Integrated Company’s strategy in the Russian and foreign markets till 2030. The Integrated Company’s strategy is being elaborated in compliance with the State Corporation ROSATOM schedule and will be approved in 2013 according to the established corporate procedures of the Company and State Corporation ROSATOM.

The NIAEP strategy till 2017 was approved by State Corporation ROSATOM and ratified by an order of the NIAEP Directorate in 2010. In the beginning of 2012 the NIAEP strategy was considerably amended in connection with the NIAEP and ASE merger. In 2013 it is planned to elaborate NIAEP-ASE Integrated Company’s strategy in the Russian and foreign markets till 2030. The Integrated Company’s strategy is being elaborated in compliance with the State Corporation ROSATOM schedule and will be approved in 2013 according to the established corporate procedures of the Company and State Corporation ROSATOM.

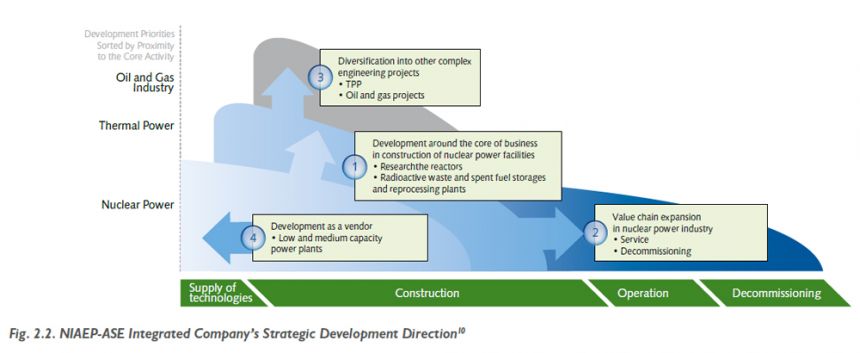

Strategic initiatives of the Company define the following approach to business development:

- Development in the main segment of operation: super power low- and medium-powered NPP construction

- Development of promising business segments which it is possible to enter on the basis of existing competencies: construction of facilities comparable to NPP with regard to complexity and scope 9.

The Integrated Company’s strategic initiatives with regard to development in the main segment of operation coincide with the strategic goals of State Corporation ROSATOM as follows: VVER Platform Global Expansion and Growth in Nuclear Power Generation in the Russian Federation (see Fig. 2.1).

Possible strategic development directions of the Integrated Company were outlined in 2012–2013 (see Fig. 2.2).

Fig. 2.2. NIAEP-ASE Integrated Company’s Strategic Development Direction 10

2012 Contribution to Strategy Implementation

In 2012 the Integrated Company performed activity aimed at implementation of the outlined strategic development directions.

1. Development around the core of business in construction of nuclear power industry facilities

- NIAEP-ASE Integrated Company acts as a general contractor and general designer of the Vietnamese Center for Nuclear Science and Technology. We also conduct negotiations on establishment of similar center in the Republic of South Africa.

- In the field of construction of storages and reprocessing plants for radioactive waste and spent fuel the Integrated Company carries out activities in the capacity of:

- - General contractor for construction of radioactive waste and spent fuel storage facilities and radioactive waste reprocessing plants;

- - Engineering and technology expert in back-end;

- - Equipment manufacturer and construction and mounting expert in the field of radioactive waste and spent fuel.

The strategic goal in this direction consists in Company development as a general contractor for construction of radioactive waste and spent fuel handling facilities with own production base and competencies in designing.

Information on performance within this strategic direction is given in Chapter 3.1. Development around the Core of Business in Construction of Nuclear Power Industry Facilities.

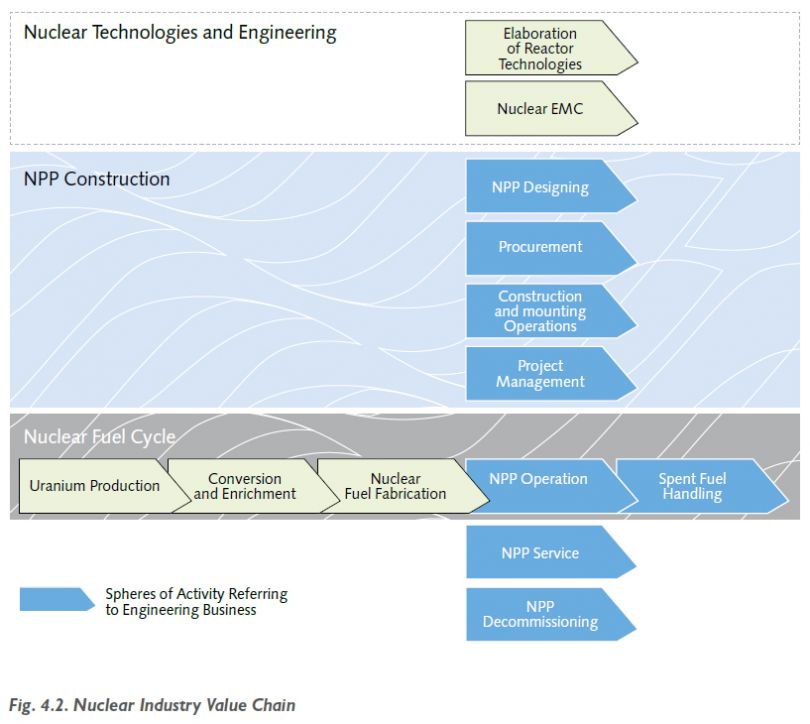

2. Value chain expansion in nuclear power industry

- In 2012 the Integrated Company performed operations on turnkey NPP construction and decommissioning of nuclear power equipment.

- In 2012 the Integrated Company rendered services at the Paks, Temelin, Bohunice, and Tianwan NPPs. The strategic goal within this direction consists in positioning of the Company as a general contractor for service operations and modernization and as an assets management consultant.

Information on implementation of this strategic direction is given in Chapter 3.2. Value Chain Expansion in Nuclear Power Industry.

3. Diversification into other complex engineering projects

- The Integrated Company has extensive experience in implementation of turnkey projects in the field of thermal power. In 2012 the Company completed construction of the Nevinnomysskaya TPP. The target vision in this direction is positioning of the Integrated Company in the capacity of a general contractor for TPP modernization and construction.

- An important direction of the Integrated Company’s strategic development consists in entering the market of oil and gas facilities construction. Currently, the Company considers the prospects of this market access. Taking into account the existing competencies, the Company may act in the capacity of a contractor with regard to some elements of work and thus participate in projects in cooperation with its partners.

Information on implementation of this strategic direction is given in Chapter 3.3. Diversification into Other Complex Engineering Projects.

4. Development as a vendor

- The Integrated Company’s activity is focused on construction of power plants. The Company is highly competent in turnkey NPP construction both in Russia, and abroad. In 2012 24 generating units abroad and 9 generating units in Russia were designed and constructed by the Company.

Information on implementation of this strategic direction is given in Chapter 3.4. Development as a Vendor.

8 It shall be noted that the Integrated Company’s strategy has not been approved yet and an overview of the planned strategic vision of the Company is given in this Report.

9 Nuclear power facilities (including back-end), TPP, LNG plants, oil refinery plants, oil platforms, oil and gas pipelines, RLNG terminals.

10 The outlined directions of strategic development of the Integrated Company are not approved and final and they can be changed in the process of further work on the Integrated Company’s Strategy elaboration.

Public Positions Concerning Sustainable Development

Public Positions Concerning Sustainable Development 11

The Company understands sustainable development as a system of successive social, economic and environmental activities making a contribution to achievement of the Company’s strategic goal together with far-sighted use of resources, workforce capacity development, and focus on scientific and technical growth.

The Integrated Company introduces principles of sustainable development into its activity taking into account current world nuclear power challenges.

The Company’s Management outlines 7 directions forming the Company’s public position in the field of sustainable development:

- Safety and quality;

- Staff development;

- Innovative activity;

- Contribution to economic development of regions of operation;

- Social responsibility;

- Environmental protection;

- Transparency and accountability.

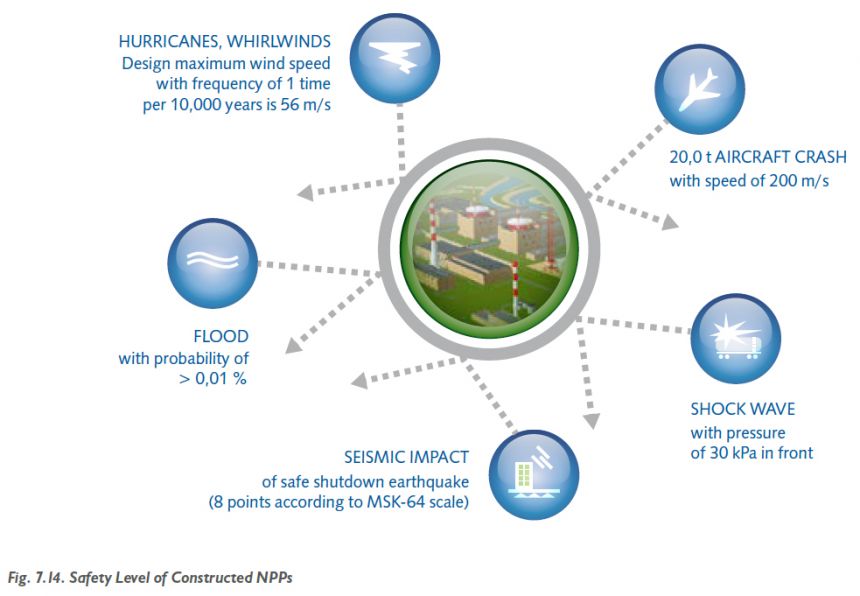

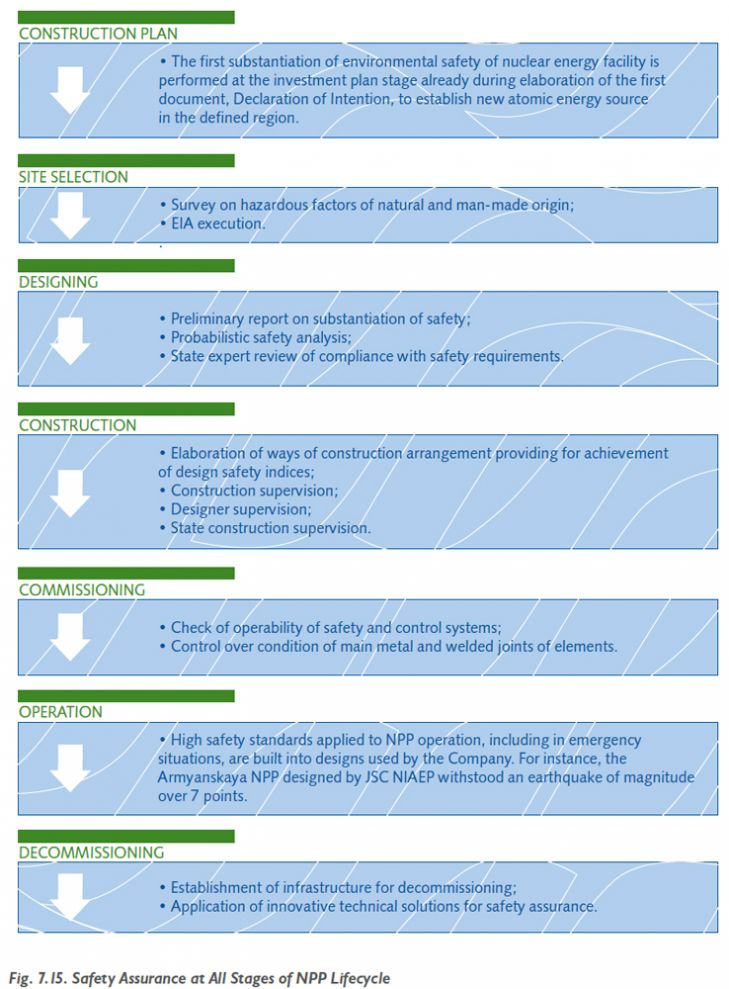

Safety and Quality

Safety and quality are the main characteristics of facilities built by the Integrated Company. In its activity the Company strictly complies with all regulatory requirements for safety established at international, national and industrial levels.

Operational safety of NPP and other facilities depends on quality of work performance at all stages of construction. The Company guarantees high level of quality, reliability and safety of the facilities constructed by it. The Company applies the Quality Management System based on the principles of the Overall Quality Management reflected in the international ISO 9000 standards. NIAEP imposes the highest requirements for the necessary level of safety to its suppliers and contractors and strictly controls the quality of work, equipment and materials.

Detailed information is specified in Chapter 7.4.5. Nuclear and Radiological Safety of Nuclear Power Facilities.

Staff Development

The Company operates in an innovative high-tech market imposing higher requirements for the level of competence of the professional team. Due to this it is important to involve the best specialist of the industry and constantly improve knowledge and skills in all key aspects necessary for implementation of our projects.

The Company provides high level of remuneration and invests significant funds in staff development. The main principles in the field of staff management of the Company include impartial assessment of professional contribution of each employee, opportunity of advancement and interdependency of remuneration level with the employee’s performance results.

Information on the Company’s effectiveness in the field of staff development is given in Chapter 7.3. Human Capital.

Innovative Activity

Technical development of the Company is based on innovative approaches to management of NPP generating units designing and construction by means of modern information technologies.

The Company attaches equal importance to the level of technological and innovative development of its partners. Aiming at collaborative innovative development with its partners, the Company established the Innovative Designing Association.

Information about innovative projects is given in Section 6. Introduction of Innovations.

Contribution to Economic Development

Implementing large-scale projects important for the economy of the regions of operation, the Company realizes its responsibility for establishment of conditions for social and economic development of these regions.

The Company’s activity leads to creation of new jobs in the regions of its operation both for suppliers, and for equipment and materials manufacturers.

Information about the Company’s effectiveness in the field of contribution to economic development is given in Chapter 7.5. Social and Economic Capital.

Social Responsibility

Sustainable development of the Integrated Company directly depends on public acceptance of the activity on construction of nuclear power facilities. The Company lays special emphasis on social stability factor and sees social responsibility as one of the key principles of its activity.

Social influence of the Company is brought both at the internal (staff), and internal levels (local communities).

The collective agreement specified the NIAEP obligations as an employer in the field of social guarantees and benefits to employees.

Information on social responsibility of the Company is given in Chapter 7.3.3. Social Policy and Chapter 7.5. Social and Economic Capital.

Environmental Protection

The maximum impact of the Company’s activity on the environment is exerted during construction of generating units.

In order to control the environmental impact of the Company’s production activity, we elaborate the necessary documents on environmental safety, plans of activities on reduction of waste generation and disposal.

NIAEP complies with the regulations of the environmental legislation, hence, is not subject to punitive sanctions.

Information about the Company’s environmental impact is given in Chapter 7.4. Natural Capital.

Transparency and accountability

Within the frames of its core activity the Company is responsible to its shareholders for performance of investment obligations. In addition, different requirements are imposed to the Integrated Company by the key interested parties, including regional authorities, local self-governing authorities, business partners and local communities. Effective cooperation with the interested parties includes assessment of their expectations and definition of the Company’s reciprocal position, as well as taking their expectations into account in corporate policies, development strategy and current activity whenever reasonable.

The Company strives to establish long-lasting and mutually beneficial relations with interested parties, respects their opinion, guarantees fulfillment of its obligations, and demands the same from the interested parties.

The Company undertakes to inform the interested parties on all aspects of its activity important for them, including public reporting mechanism.

Information on fulfillment of the transparency and accountability principles in the Company’s activity is given in Chapter 7.6. Relations with Interested Parties.

11 The Company’s public position in the field of sustainable development is described in detail in the JSC NIAEP 2011 Annual Report.

PERFORMANCE RESULTS OF STRATEGIC IMPORTANCE

Development around the Core of Business in Construction of Nuclear Power Industry Facilities

Research Reactors

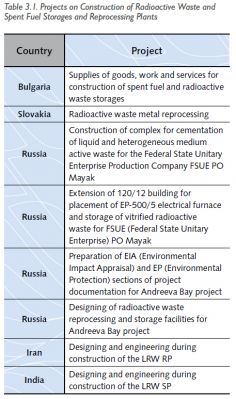

Table 3.1. Projects on Construction

of Radioactive Waste and Spent

Fuel Storages and Reprocessing Plants

In 2012 the Integrated Company participated in construction of a research reactor in Vietnam.

Vietnam. Nuclear Science and Technology Center (NSTC)

Project description. In 2011 Russia and Vietnam concluded the Intergovernmental Agreement on Construction of the Nuclear Science and Technology Center for (NSTC) in Vietnam. ASE was appointed the project’s general contractor. NSTC construction is planned for the period from 2014 to 2019.

2012 results. In 2012 the Russian party elaborated the Materials for Preliminary Feasibility Study on the Nuclear Science and Technology Center (NSTC) in the Socialist Republic of Vietnam, which was submitted to the customer on November 21, 2012.

2013 arrangements:

- Approval of a site for laboratory with non-reactor technologies;

- Conclusion of the contract on FS-JOI elaboration.

Radioactive Waste and Spent Fuel Storages and Reprocessing Plants

In 2012 the Integrated Company carried out work within 8 projects on construction of storages and reprocessing plants for radioactive waste and spent fuel (see Table 3.1).

Bulgaria. Supplies of Goods, Work and Services for Construction of Spent Fuel and Radioactive Waste Storages

Project description. The project is executed within the partnership agreement concluded between the Integrated Company and Risk Engineering Ltd. (Bulgaria). Risk Engineering Ltd. is the customer of the project. NIAEP-ASE Integrated Company acts as the general contractor.

2012 results. The following work was performed: supplies of goods, work and services required for construction of spent fuel and radioactive waste storages, supplies of containers for spent fuel and radioactive waste transportation and storage and systems for transportation of containers, supplies of units, systems and plants for radioactive waste reprocessing, transportation, storage and burial, and rendering of services on NPP decommissioning, including designing, procurement of equipment (instruments and mechanisms), and deactivation and demounting services.

Slovakia. Radioactive Waste Metal Reprocessing

Project description. In March 2008 ASE signed a contract with the customer of the project, YAVIS Ltd. (Slovakia). The Integrated Company is the general contractor of the project. The contract does not stipulate for completion date.

2012 results. Import of radioactive waste metal to the territory of the Russian Federation for reprocessing is forbidden, due to this contractual work was suspended, in order to find ways for fulfillment of obligations.

Russia. Construction of Complex for Cementation of Liquid and Heterogeneous Medium Active Waste for FSUE PO Mayak

Project description. In July 2008 ASE concluded contract with the customer of the project, State Corporation ROSATOM. The Integrated Company performs work on a turnkey basis. It is planned to complete work in December 2013.

2012 results. The following work within the project was completed in 2012:

- Mounting of utility networks, heavy process equipment, ventilation and heating systems;

- Building inner finish;

- Mounting work and supply of additional equipment ordered by the customer at the end of 2011;

- Casting of foundation plates for radioactive waste storage;

- Mounting of metal structures (lining of compartments) for main construction facilities;

- Energy utilities construction;

- External lines arrangement;

- Mounting of concrete reinforcement of the process building and corrosion-resistant lining;

- Erection of cast-in-situ walls and floors;

- Mounting of heavy equipment.

Further plans under the project include completion of work, signing of work completion certificate, and, later on, fulfillment of obligations within the guarantee period.

Russia. Extension of 120/12 Building for Placement of EP-500/5 Electrical Furnace and Storage of Vitrified Radioactive Waste for FSUE PO Mayak

Project description. The project is executed within the intergovernmental agreement concluded between Russia and Italy and stipulating for cooperation in the field of disposal of Russian nuclear submarines decommissioned from the naval forces and safe handling of radioactive waste and spent fuel. The agreement was concluded on November 5, 2003. Work is performed on a turnkey basis. The customer of the project is State Corporation ROSATOM. Contractual work was launched in October 2010, it is planned to complete the project in December 2013. The total cost of the project amounts to 1,552,163 thousand rubles. The project is financed from federal budget resources of the Russian Federation within implementation of the Federal Target Program on Nuclear and Radiation Safety in 2008 and up to 2015.

Project description. The project is executed within the intergovernmental agreement concluded between Russia and Italy and stipulating for cooperation in the field of disposal of Russian nuclear submarines decommissioned from the naval forces and safe handling of radioactive waste and spent fuel. The agreement was concluded on November 5, 2003. Work is performed on a turnkey basis. The customer of the project is State Corporation ROSATOM. Contractual work was launched in October 2010, it is planned to complete the project in December 2013. The total cost of the project amounts to 1,552,163 thousand rubles. The project is financed from federal budget resources of the Russian Federation within implementation of the Federal Target Program on Nuclear and Radiation Safety in 2008 and up to 2015.

2012 results. The following work was completed in 2012:

- Extension girder construction and reinforcement for EP-500/5 placement;

- Pile field driving for radioactive waste storage;

- Territory improvement;

- Removal of existing utility networks from the construction site.

- Extension frame erection for EP-500/5 placement and radioactive waste storage;

- Partial supply of process equipment.

Further plans under the project include completion of work on mounting of frame structures of the storage, completion of work on cast-in-situ structures, first-stage supply of nonstandard equipment; in the longer term: completion of work in 2015, fulfillment of obligations within the guarantee term.

Russia. Preparation of EIA and EP Sections of Project Documentation for Andreeva Bay Project

Project description. The Project is executed within the intergovernmental agreement concluded between Russia and Italy and stipulating for cooperation in the field of disposal of Russian nuclear submarines decommissioned from the naval forces and safe handling of radioactive waste and spent fuel. In 2010 for performance of work under the project ASE and the Federal State Unitary Enterprise Federal Nuclear and Radiation Safety Center (FSUE FNRSC) signed contract on elaboration of EIA and EP sections of project documentation. The customer of the project is FSUE FNRSC. It is planned to complete the project in June 2013. The scope of responsibility of the Integrated Company includes coordination of the Russian subcontractors during designing, supply and construction of radioactive waste reprocessing and storage plants at the Andreeva Bay facility.

2012 results. The project documentation including EIA and EP sections for radioactive waste reprocessing and temporary storage plants was elaborated in the reporting year.

Further plans under the project include completion of work, fulfillment of obligations within the guarantee term.

Russia. Designing of Radioactive Waste Reprocessing and Storage Facilities for Andreeva Bay Project

Project description. The goal of the project consists in establishment of infrastructure for radioactive waste disposal in the territory of the former technical base of naval forces. In February 2011 the contract was concluded between ASE and Ansaldo Nucleare (Italy) on elaboration of the Andreeva Bay project documentation. The project is executed within the intergovernmental agreement concluded between Russia and Italy and stipulating for cooperation in the field of disposal of Russian nuclear submarines decommissioned from the naval forces and safe handling of radioactive waste and spent fuel. The customer of the project is Ansaldo Nucleare. It is planned to complete the work in June 2013. The scope of responsibility of the Integrated Company includes coordination of the Russian subcontractors during designing, supply and construction of radioactive waste reprocessing and storage plants at the Andreeva Bay facility.

2012 results. In 2012 the project documentation including EIA and EP sections was elaborated for radioactive waste reprocessing and temporary storage plants at the Andreeva Bay facility.

Further plans under the project include completion of work, fulfillment of obligations within the guarantee term.

Iran. Designing and Engineering during Construction of the LRW Reprocessing

Plant (LRW RP)

Project description. Since 2008 the Integrated Company has performed design elaboration and field supervision of equipment manufacturing for the LRW reprocessing plant (LRW RP) within the frames of the contract on construction of the Bushehr NPP first generating unit. The customer of the project is the Nuclear Power Production and Development Company of Iran, the general contractor is NIAEP-ASE Integrated Company.

2012 results. In the reporting year the Integrated Company completed mounting and start-up operations on establishment of the LRW reprocessing plant. We proceeded with LRW RP commissioning and launching of operation under design conditions.

Further plans under the project include LRW RP commissioning, field supervision of integrated testing and commissioning, correction of maintenance and construction documentation according to the results of start-up operations, field supervision of LRW casks manufacturing, staff training, and fulfillment of obligations within the guarantee term.

India. Designing and Engineering during Construction of LRW Solidification Plant

Project description. Since August 2008 the Integrated Company has elaborated design of the liquid radioactive waste solidification plant (LRW SP) and performed field supervision of equipment manufacturing within the contract on construction of Kudankulam NPP generating units 1 and 2. Work is carrying out under the internal order within fulfillment of obligations under the contract on construction of Kudankulam NPP generating units 1 and 2. The project customer is Atomic Energy Corporation of India, LTD. It is planned to complete the project in 2013.

2012 results. The Integrated Company has carried out mounting, start-up and commissioning of the cementation plant (CP), concentrating facility (CF) units, and CP and CF I&C systems.

Further plans under the project include commissioning of LRW SP, field supervision over mounting, start-up, integrated testing and commissioning, correction of maintenance and construction documentation according to start-up results, and staff training.

International Cooperation in the Field of Radioactive Waste and Spent Fuel Handling

Working group was established, including specialists of ASE, Nukem Technologies (Germany) and the Russian Federal Nuclear Center – the Russian Research Institute of Experimental Physics (RFNC – VNIIEF), for consolidation of efforts in introduction of joint concept on arrangement of centralized long-term storage of the Russian nuclear power stations’ spent fuel assembly at FSUE GKH with application of cask storage technologies.

In June 2011 ASE and RFNC – VNIIEF signed the agreement on strategic partnership in the field of spent nuclear fuel handling. OJSC State Specialized Planning Institute (SSPI), OJSC SverdNIIKhimmash, NUKEM Technologies, ASE and NIAEP concluded the agreement on cooperation during turnkey execution of projects in the field of decommissioning of nuclear and radiation dangerous facilities (DNRDF), and spent fuel and radioactive waste handling. Cooperation is aimed at competitive growth, accumulation of competencies and creation of opportunity for distribution of experience in Russia, as well as further entrance to the global market. The partners have experience and competence in the following fields:

- OJSC SSPI – performance of project and construction operations for the needs of the nuclear industry of Russia;

- OJSC SverdNIIKhimmash – elaboration, manufac-turing and supply of equipment for nuclear power plants and fuel cycle facilities;

- NUKEM Technologies – technologies and equipment for DNRDF and spent fuel and radioactive waste handling;

- ASE – construction of nuclear power plants with reactors of Russian design and turnkey construction of nuclear facilities and units on the basis of EPCM model;

- NIAEP – construction and commissioning of nuclear power plants in Russia and abroad.

Value Chain Expansion in Nuclear Power Industry

Service

The Integrated Company rendered services for the following nuclear power plants: Paks, Temelin, Bohunice, and Tianwan.

Hungary. Paks NPP, Generating Units 1 to 4

Project description. The Company performs work within execution of the long-term framework contract concluded with CJSC Paks NPP for supply of equipment and components to provide operation of Paks NPP units 1 to 4. The current framework contract is in force from 2011 to 2014.

2012 results. In 2012 the Company fulfilled obligations in accordance with the contract. The scope of work performed amounted to 20.55 million rubles. The annual work plan was fulfilled 100 percent.

2013 arrangements. Plans for 2013 include rendering of consultation services under the executed contracts.

Czech. Temelin NPP, Generating Units 1 and 2

Project description. The work is carried out on the basis of three indefinite-term contracts for rendering of engineering and consultation services during NPP operation concluded with CEZ a.s.

2012 results. In 2012 the Company fulfilled obligations in accordance with the contract. The scope of work performed amounted to 5.89 million rubles. The 2012 annual work plan was fulfilled at 100%.

2013 arrangements. Plans for 2013 include rendering of consultation services under the executed contracts.

Slovakia. Bohunice NPP, Generating Units 3 and 4

Project description. The Company performed work on modernization of the Bohunice NPP within the guarantee obligations. Service operations under the project started in 2002. The scope of responsibility of the Company included replacement of NFCE systems, and in the period from 2008 to 2012 work within the guarantee obligations.

2012 results. The Company performed obligations in accordance with the concluded contracts. 2012 the guarantee obligations under the project were completely fulfilled.

2013 arrangements. Work under the project is completed; no plans are scheduled for 2013.

China. Tianwan NPP, Generating Units 1 and 2

Project description. The facility was commissioned in 2007. In 2011 the contract was concluded on substantiation of opportunity to increase the time between overhaul of the equipment, systems and pipelines of Tianwan NPP units 1 and 2 during transition to an 18-month fuel cycle from a 12-month one. The work completion time is 2013. In addition, in 2011 JNPC and the Company signed the contract on extraction of surveillance specimen from the reactor body by means of MP394 manipulator with attraction of specialists of OJSC NIKIMT-Atomstroy.

2012 results. In 2012 the Company performed obligations in accordance with the concluded contracts.

2013 arrangements. Plans for 2013 include contract completion and provision of a rational for change-over on 18-month-long cycle and also rendering of consultation services under the executed contracts.

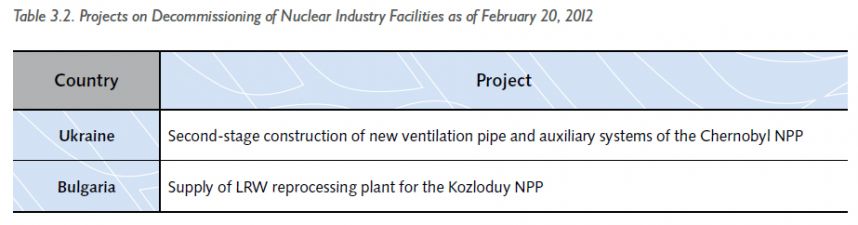

Decommissioning

In 2012 the Integrated Company carried out work on 2 projects in 2 countries (see Table 3.2) within rendering of decommissioning services.

Table 3.2. Projects on Decommissioning of Nuclear Industry Facilities as of February 20, 2012

Ukraine. Second-Stage Construction of New Ventilation Pipe and Auxiliary Systems of the Chernobyl NPP

Project description. The project is executed within operations on Object Shelter (sarcophagus) of the Chernobyl NPP. For participation in the tender on performance of work within this project the Shelter consortium was established (ASE, being the leader, and PJSC Ukrenergomontazh). Conclusion of a design contract between the Shelter consortium and the state specialized enterprise Chernobyl NPP is scheduled for 2014. The customer of the project was the International Fund Shelter. Work under the project was launched in July 2010; completion of work is scheduled for September 2013. The total cost of the project amounts to USD 9,361,382.

Project description. The project is executed within operations on Object Shelter (sarcophagus) of the Chernobyl NPP. For participation in the tender on performance of work within this project the Shelter consortium was established (ASE, being the leader, and PJSC Ukrenergomontazh). Conclusion of a design contract between the Shelter consortium and the state specialized enterprise Chernobyl NPP is scheduled for 2014. The customer of the project was the International Fund Shelter. Work under the project was launched in July 2010; completion of work is scheduled for September 2013. The total cost of the project amounts to USD 9,361,382.

2012 results. Work on construction of vent pipe was completed. We also proceeded with mounting of radiation control systems and auxiliary systems at the Chernobyl NPP.

Further plans under the project include completion of work, signing of work completion certificate; and later on fulfillment of obligations within the guarantee period.

Bulgaria. Supply of LRW Reprocessing Plant for the Kozloduy NPP

Bulgaria. Supply of LRW Reprocessing Plant for the Kozloduy NPP

Project description. The project is executed within the frames of international program on decommissioning of units 1, 2, 3 and 4 of the Kozloduy NPP, Bulgaria. The project is aimed at treatment of water discharged to Danube and formed during decommissioning of the generating units. In 2004 the contract was signed within the tender of the European Bank for Reconstruction and Development, in 2005 project plan was elaborated, and supply of the equipment was completed in 2009.

2012 results. Test operations regarding the project are finished. The liquid radioactive waste reprocessing plant is commissioned.

Further plans under the project include fulfillment of obligations within the guarantee term (guarantee term expires in 2014).

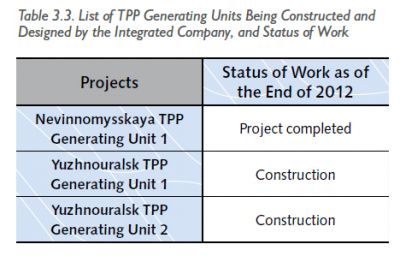

Diversification into Other Complex Engineering Projects

Table 3.3. List of TPP Generating

Units Being Constructed and Designed by

the Integrated Company, and Status of Work

Further plans under the project include fulfillment of obligations within the guarantee term (guarantee term expires in 2014).

Further plans under the project include fulfillment of obligations within the guarantee term (guarantee term expires in 2014).

In 2012 the Integrated Company carried out construction of two thermal power plants: the Nevinnomysskaya TPP and the Yuzhnouralsk TPP (see Table 3.3).

Stavropol Territory. Nevinnomysskaya TPP

Project description. In 2008 OJSC OGK-5 and the consortium of ENEL Produzione S.p.A. and ASE signed the contract on management of engineering, procurement and construction of the generating unit of the combined cycle gas turbine plant (CCGTP) with a capacity of 410 MW on the site of the Nevinnomysskaya TPP. The consortium executed this project on the basis of EPCM model. The scope of responsibility of the Integrated Company within this project included performance of engineering survey on the site, preparation of feasibility study (FS) and working design estimate specification (DES), supply of accessories, general construction operations (including supply of building materials), mounting of the equipment, assistance in start-up of the generating unit equipment, and modernization of high-voltage 330 kV substation on a turnkey basis. The customer of the project was OJSC OGK-5.

2012 results. Construction of the second, third and fourth start-up facilities was completed. The power plant construction was finished in due course. Consortium prepared, signed and passed to the customer the End Facility Acceptance Certificate and the Certificated of End Facility Acceptance by the Acceptance Committee. In 2012 the profit with respect to the project amounted to nearly 20.7 million USD excluding VAT.

2013 arrangements. Signing of the specified certificated by the customer is scheduled for 2013.

Chelyabinsk Region. Yuzhnouralsk TPP-2

Project description. In 2009 ASE and OJSC OGK-3 signed the contract on construction of energy complex of Yuzhnouralsk TPP-2 on the basis of the EPC model. The customer of the project is OJSC OGK-3. According to the technical solution of the customer, the energy complex of the Yuzhnouralsk TPP-2 is a condensate combined cycle power plant (CCCPP) including three generating units with a capacity of 400 MW each with additional structures and utility lines. ASE put forward a proposal on construction of three 415 MW single-shaft generating units on the basis of Siemens Power Island (gas turbine power plant, steam turbine power plant, and generator) and three-loop waste-heat recovery unit.

2012 results:

Generating Unit 1

In 2012 start-up operations were carried out and 90 percent completed by the end of the year. 2012 the profit with respect to the project amounted to nearly 12 billion rubles excluding VAT.

Generating Unit 2

On May 14, 2012 the general contractor contract was signed. 80 percent of working documentation was prepared by the end of the reporting period. In addition, in 2012 operations of the preparatory stage were fulfilled including vertical leveling, commissioning of temporary electricity supply, construction of motor highway and administrative building, arrangement of main building pit, foundations for main building structures, waste-heat recovery unit and smoke stack, mounting of main building metal structures. In 2012 the profit with respect to the project amounted to nearly 173 million rubles excluding VAT.

2013 arrangements:

Generating Unit 1

In 2013 it is planned to completed start-up and commissioning of the unit (planned date of commissioning September 30, 2013). Final completion of project operations is scheduled for October 2013.

Generating Unit 2

The main tasks for 2013 include completion of the main building thermal envelope (by the end of December), supply and mounting of the Power Island equipment. In 2013 it is planned to complete main construction operations, major part of work on equipment mounting, and to launch start-up.

Development as a Vendor

NPP Construction Abroad

In 2012 the Integrated Company performed operations on designing and construction of generating units of nuclear power plants in India, Iran, Belarus, Slovakia, Turkey, China, Ukraine, Vietnam and Bangladesh (see Table ).

This included construction of 7 generating units as follows: Bushehr NPP generating unit 1; Kudankulam NPP generating units 1 and 2; Belarusian NPP generating units 1 and 2; and Tianwan NPP generating units 3 and 4.

Table 3.4. List of NPP Generating Units Being Constructed and Designed by the Integrated Company Abroad, and Status of Work

Iran. Bushehr NPP, Generating Unit 1

Project description. In 1976 the contract was concluded with the German trust Kraftwerk Union A. G. (Siemens/KWU) on construction of Bushehr NPP generating unit 1. The project construction was launched in 1995. The Customer of th

e project was the Atomic Energy Organization of Iran (AEOI). In October 2010 ASE obtained the license for NPP commissioning. The scope of responsibility of the Integrated Company in respect of this project includes commissioning.

The Bushehr NPP is constructed on the basis of VVER-446 project; all operations are carried out in accordance with the international standards, legislation, and non-proliferation regime, and are controlled by IAEA. It is planned to complete the project in 2015.

2012 results. 52 percent of annual work plan was completed according to the Bushehr NPP construction schedule. As of December 31, availability of Bushehr NPP generating unit 1 amounted to 99.85%, and the contribution of 2011 to the level of the project availability was only 0.16%. On August 30, 2012 Bushehr NPP generating unit 1 was launched at 100% of design capacity.

2013 arrangements. Field trial of the unit is scheduled for 2013.

India. Kudankulam NPP, Generating Units 1 and 2

Project description. In accordance with the cooperation agreement on construction of a nuclear power plant in India signed 1988 between the USSR and the Republic of India, the Russian Federation renders technical support to India in construction of two generating units of the Kudankulam NPP with VVER-1000 reactor units. It is planned to construct a total of 6 generating units at this NPP. In 2001 designing work was launched, in 2002 construction began.

After consolidation of NIAEP and ASE, execution of the Agreement on Construction of Kudankulam NPP Units 1 and 2 is performed by the Integrated Company on the Russian part and the Nuclear Power Corporation of India Limited (NPCIL) on the Indian part. The customer of the project is NPCIL.

The scope of responsibility of the Integrated Company within the project includes elaboration of project, start-up and maintenance documentation, supply of equipment and materials, rendering technical support during NPP construction, mounting and commissioning, as well as training of Indian staff.

2012 results. In 2012 construction of generating units 1 and 2 was carried out at the Kudankulam NPP. The work plan on construction of the generating units was completed 100 percent. Availability of generating unit 1 amounted to 100% and of generating unit 2 to 98%. Contribution of the reporting period to the project availability is 2 to 3%. The volume of work performed amounted to 51 million USD. The following results were achieved in the reporting period:

2012 results. In 2012 construction of generating units 1 and 2 was carried out at the Kudankulam NPP. The work plan on construction of the generating units was completed 100 percent. Availability of generating unit 1 amounted to 100% and of generating unit 2 to 98%. Contribution of the reporting period to the project availability is 2 to 3%. The volume of work performed amounted to 51 million USD. The following results were achieved in the reporting period:

- Work on generating unit 1 in accordance with the 2nd revision program completed;

- Work on generating unit 1 in accordance with the reactor start-up program launched;

- Process systems of generating unit 2 washed and hydro-tested;

- Functional testing of equipment of generating unit 2 started.

2013 arrangements. The expected 2013 contribution to the level of project availability is 2 percent. The following types of operations are scheduled for 2013:

- Launch of generating unit 1 at minimum controllable power;

- Synchronization and first network connection of the unit 1 generator;

- 50, 75, and 100% power testing of generating unit 1;

- Operations on the program of hydraulic testing and circulation flushing on generating unit 2;

- Hot operational testing of generating unit 2;

- Launch of operations within the reactor start-up program on generating unit 2.

Generating Units 3 and 4

Project description. Generating units 3 and 4 of the Kudankulam NPP will be also designed on the basis of VVER-1000 platform. The scope of responsibility of the Integrated Company within this project includes designing, supply of equipment and delegation of specialists for technical support.

2012 results. In 2012 initial project work was carried out including adjustment of technical and commercial proposal and conclusion of general framework agreement with the project customer.

2013 arrangements. Designing of generating unit 3 is scheduled for 2013. The key activities scheduled for 2013 include:

- Final approval of the technical and commercial proposal for construction of Kudankulam NPP generating units 3 and 4;

- Conclusion of the General Framework Agreement.

Belarus. Belarusian NPP. Generating Units 1 and 2

Project description. In 2011 the intergovernmental agreement was concluded between Russia and Belarus onconstruction of the Belarusian NPP. According to the agreement, ASE was appointed general contractor of the Belarusian NPP construction project, and the State Enterprise Nuclear Power Plant Construction Directorate (GU DSAE) acted as the customer. The Belarusian NPP will include two generating units with VVER-1200 reactors (V-491) with a capacity of up to 1,200 MW each. The gross installed capacity will amount to 2,400 MW. The commissioning of generating unit 1 is scheduled for 2018 and of unit 2 for 2020.

2012 results. In 2012 work was launched on designing of the Belarusian NPP. By the end of the year, 963 people worked on the project, number of construction machines engaged amounted to 260 units. By the end of 2012, availability of the project equaled to 10 percent, and 65% of the project documentation was elaborated. The following results were achieved in the reporting period:

- Designing of the foundation pit for generating unit 1;

- Initial designing of the foundation pit for generating unit 2.

2013 arrangements. The following operations are scheduled for 2013:

- Completion of work on concrete foundation arrangement for generating unit 1;

- Completion of soil excavation for the foundation pit and waterproofing of main buildings and structures of generating unit 2;

- Completion of work on concrete foundation arrangement for generating unit 1.

Turkey. Akkuyu NPP, Generating Units 1–4

Project description. In 2010 the intergovernmental agreement was signed between Russia and Turkey on cooperation in the field of construction and operation of the nuclear power plant. ASE was appointed general contractor of the project, and Akkuyu NGS A.S. acted as the customer.

In 2011 work was started on execution of the Akkuyu NPP project which includes construction of 4 generating units of AES-2006 type with VVER-TOI platform and total capacity of 4,800 MW.

2012 results. The scope of the work performed within the project amounted to 39 million USD. 84.3 percent of the annual work plan was completed. The 2011 contribution to the level of the project availability amounted to 0.02 percent, and the level of availability was 0.25% by the end of 2012.

In 2012 the general contractor performed the following operations within the Akkuyu NPP project:

- Engineering explorations at the design stage;

- Survey of the site’s rocky soils to determine the possibility of their application for preparation of building materials during NPP facilities construction;

- Turkey market analyses;

- Survey of the existing site infrastructure;

- Elaboration of draft design for camp construction for operational staff;

- Tender for selection of contractor for excavation and site relief arrangement at the first stage.

2013 arrangements. The expected 2013 contribution to the level of the project availability will amount to 0.43%. The list of key scheduled operations includes:

- Signing of a contract with contractor on preparatory stage works (off-site access routes, complex of off-site facilities of potable water supply of Akkuyu NPP, temporary inhabited area for Akkuyu NPP constructors, building and installation facilities for Akkuyu NPP construction, cargo terminal);

- Engineering surveys and production of design and operational documentation for the facilities of preparatory stage (off-site access routes, complex of off-site facilities of potable water supply of Akkuyu NPP, temporary inhabited area for Akkuyu NPP constructors),

- Termination of temporary infrastructure facilities repair on site, including system of reliable energy supply,

- Start of engineering surveys of the stage ‘’Operational Documentation’’,

- Monitoring of Akkuyu NPP site.

China. Tianwan NPP (TNNP), Generating Units 3 and 4

Project description. Generating units 3 and 4 refer to the second stage of the Tianwan NPP, are located on the NPP site in Jangsu Province (China) and border with TNNP generating units 1 and 2 (first stage) which were commissioned in 2007 and transferred to the Chinese customer after trial guarantee operation on April 15, 2010. The Tianwan NPP second stage (TNPP-2) is being constructed in accordance with the General Contract on the TNPP Generating Units 3 and 4 Construction which entered into force in 2011. The customer of the project is Jangsu Nuclear Power Corporation (JNPC). The service supplier is NIAEP-ASE Integrated Company. In accordance with the General Contract on the TNPP Generating Units 3 and 4 Construction, the Integrated Company is obliged to elaborate design and supply equipment for nuclear island (NI), and also bears general technical responsibility for the NPP project in whole.

The planned term of commissioning of the generating units: generating unit 3 in February 2018, generating unit 4 in December 2018.

2012 results. In 2012 the Company performed elaboration of technical design documentation packs, including technical specifications for procurement of equipment in China and third countries, as well as documents for obtaining the permits required to launch construction of generating units 3 and 4 of TNNP. In December 2012 JNPC obtained the permit for construction of TNNP-2 generating units 3 and 4. In 2012 the total cost of work on construction and designing of TNPP generating unit 3 amounted to 14.8 million euro. 100% of the annual work plan was completed. The TNNP-2 availability level amounted to 5.19 percent by the end of 2012, the contribution of the previous year to the level of the project availability equaled to 1.21%.

The key 2012 activities on construction of TNNP generating units 3 and 4 include:

- Procurement of building permit for construction of both generating units;

- Start of construction (first concrete casting) of generating unit 3.

2013 arrangements. Generating unit 4 construction shall start on October 20, 2013. The expected 2013 contribution to the TNPP-2 availability level shall equal to 4.77%. In this connection the main plans for 2013 include:

- Final transfer of the first-priority NF working documentation for generating units 3;

- Supply of equipment for first concrete casting on generating unit 4;

- First concrete casting on generating unit 4.

Ukraine. Khmelnitskaya NPP, Generating Units 3 and 4

Project description. In 2010 the Government of the Russian Federation and the Cabinet of Ministers of Ukraine concluded an agreement on cooperation in construction of Khmelnitskaya NPP generating units 3 and 4. According to the agreement ASE was appointed general contractor and State Enterprise GP NAEK Energoatom acted as the customer of the construction of generating units 3 and 4 of Khmelnitskaya NPP. The signing of contract is scheduled for 2014. To ensure the delivery of an agreement dated 09.02.2011 between ASE and GP NAEK Energoatom a contractual arrangement was signed for the development of technical project (TP) of reactor plant (RP) VVER-1000/B-392 and the equipment supply of RP for generating units 3 and 4 of the Khmelnitskaya NPP, which is marked by frame character and provides a phased signing of series of contracts by parties.

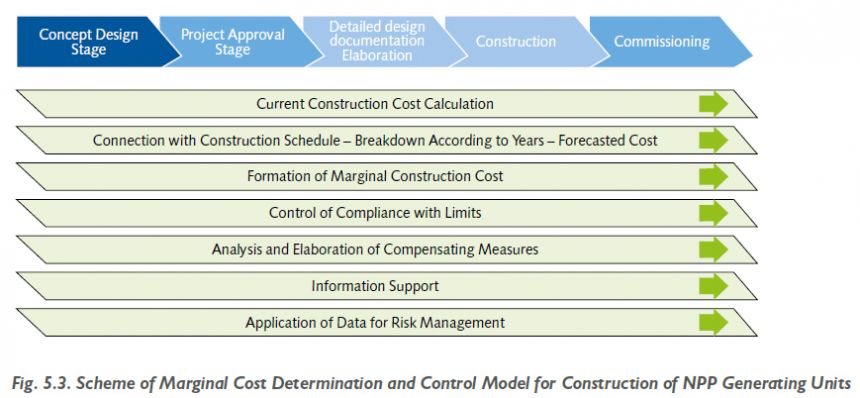

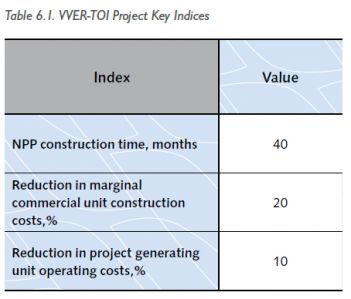

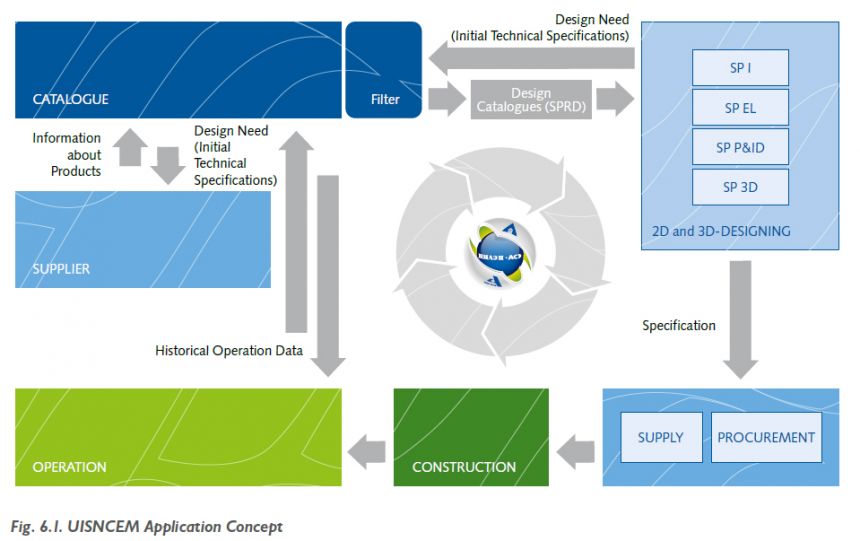

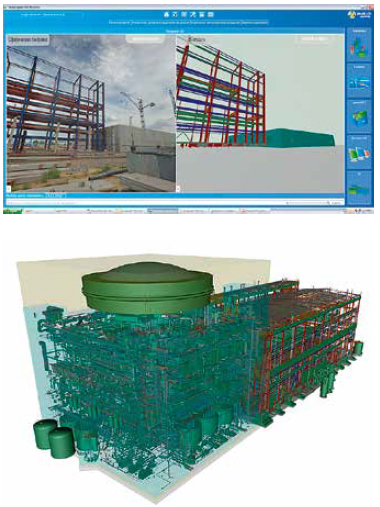

The expected years of commissioning of Khmelnitskaya NPP generating units 3 and 4 are 2020 and 2021 accordingly.